Air, or more correctly, air pressure is what allows your truck air brakes to operate properly. If the pressure is weak the brakes won’t engage properly.

DISCOVER 100 BEST TOOLS TO RUN TRUCKING BUSINESS

Hey! I'm George J. Magoci and I will send you a FREE eBook where you can Discover 100 Best Tools to Run Trucking Business.

Imagine being on that icy road without truck and trailer brakes! That can be a scary thought, especially if you’re heading downhill in some of the most dangerous roads for drivers, like: the Ozarks or the Rocky Mountains.

Often air will bleed out of your brakes and it might take a little time to build it back up. That is fine; don’t risk trying to drive off without proper pressure.

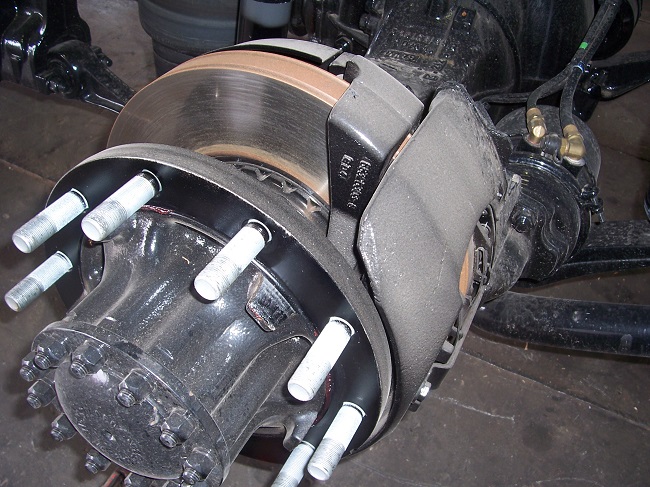

Source: www.commons.wikimedia.org

4. How do you Test your Truck Air Brakes?

This is very important and is something that should have been taught prior to getting your truck air brakes endorsement.

But it might have been a while since you tested. Perhaps you work at a place where the mechanic does all the truck air brakes testing. So here are some basic steps for testing your trucks air brakes.

- The first thing is your seatbelt, buckle up for safety!

- After starting your truck build up the pressure (90-110 lbs)

- Check your parking brake by, applying the parking brake, shift into gear, releasing the clutch and attempting to move, it should not.

- Charge your truck’s air system

- Allow the airlines to fill

- It will take about a minute to be able to check for leaks, (no more than 2 psi)

- Apply 90 pounds of pressure and hold for about one minute

- 3 psi should be the maximum leakage

- Pumping the brakes, should cause the light/alarm to activate (at about 60 pounds)

- If you keep pumping, the truck’s protection valve should pop out (20 to 40 psi)

- Running and in neutral check to see how long it takes for the pressure to build back up (should build to between 85 and 100 psi)

- As the pressure builds the air governor should blow out (between 125 and 130 psi).

Source: www.efolio.lattc.edu