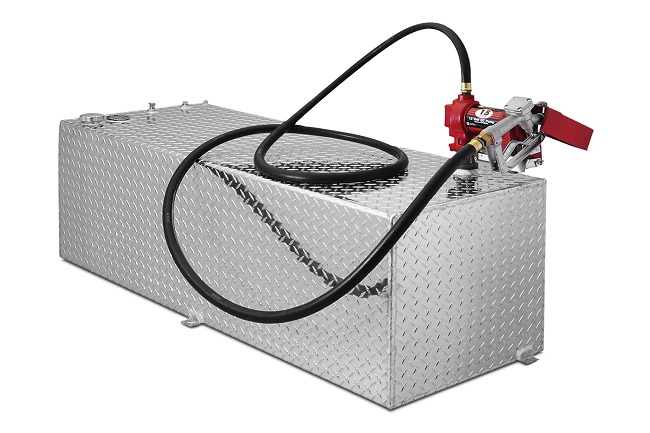

The most common materials that are used in the tank manufacturing industry are:

- Aluminum

- Steel

- Stainless steel

Choice of tank material is made of the possibility that the material has to be cut, shaped and properly welded in order to be bonded strongly to the metal.

Aluminum Fuel Tanks

Characteristics of these types of tanks:

- Lighter tanks bring less weight (aluminum is used to reduce the weight of the truck, 2,300 pounds in a typical tractor) and that means lower fuel consumption

Source: www.michos-tank.com

Source: www.michos-tank.com

- Aluminum is corrosion resistant

- Not so vulnerable to corrosion (inside the tank from low sulfur fuel)

- Not prone to rust and corrosion caused by moisture (outside the tank)

Steel Fuel Tanks

- Steel is one of the least expensive fuel tank materials, but it is very strong and not so flexible for shaping or cutting

- Bigger weight means increased fuel consumption

- These fuel tanks are more exposed to the corrosion or rust and that is why steel tanks should be degreased and coated after the manufacturing process is complete. In this way, oxidation and rust formation is minimized but still possible

Stainless Steel Fuel Tanks

- Is long lived material and it is very practical for fuel tanks

- This fuel tank will serve you well, but you need to ensure that it has enough oxygen if it is wet